Last Updated on March 19, 2023

Polyurethane bushings often produce squeaking or creaking sounds in your automobiles. The noise is usually caused by friction between the rubber and the metal it is mounted to.

Ultimately, the consequences are awful, as they can permanently damage the parts. Many of our daily products utilize them, including cars. The synthetic material makes them so versatile, as it provides a balance of firmness and flexibility.

If your motor vehicle has rubber parts, you may have noticed a squeaking or creaking noise. There are a few ways to turn down these components so that you can enjoy a smoother, silent ride. Through this guide, you can learn how to quiet polyurethane bushings.

How to Quiet Polyurethane Bushings By Using Simple Methods?

Polyurethane bushings are a great way to upgrade your ride quality and noise reduction. These cushions feature a soft cover that is energy absorbent, offering a smoother journey. They also isolate vibrations and sound, making for a more pleasant driving experience.

These materials are more durable than rubber, so you can enjoy the benefits of quieter travel for years to come. When shopping for plastic bearings, be sure to check for compatibility with your make and model of car. Once installed, these bumps will help you enjoy the road like never before.

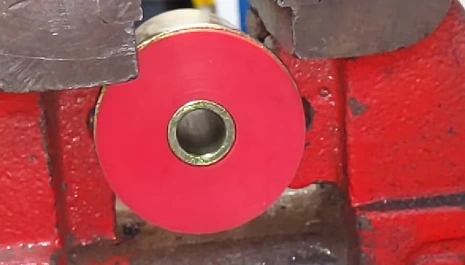

1. Lubricate the Bushings

If you’re looking for a way to reduce the noise without sacrificing performance, then lubricating the bushings is a good option. This can be done with a variety of different lubricants, such as silicone spray or WD-40.

Simply spray the lubricant onto it and work it into the crevices. This will help to lessen the amount of conflict between rubber and braking components, which will, in turn, make the car quieter.

2. Replace the Bushings

While most people associate car noise with engine issues, many times it is actually caused by faulty automotive components. Worn suspension parts are the primary cause of rattles, squeaks, and other unwanted vehicle sounds.

If your car is making noise, one of the first places to check is the condition of the mechanical system. If they are out of date, replacing them with quiet polyurethane bushings is a relatively simple and inexpensive repair that can make a big difference in the ride quality of your vehicle.

3. Add Sound Deadening Material

When you want a more permanent solution, you can try adding acoustic material to your automobile. This will help reduce the overall noise level inside your car’s cabin. There are a number of substances that can be used for this purpose, such as Dynamat or Noico.

Simply apply the adhesive to the inside of your auto, being sure to cover any areas where sound may be coming from. This method is a bit more involved than the other methods, but it’s well worth the effort if you want to achieve maximum quietness.

4. Upgrade to an Aftermarket Suspension

An effective method for reducing road noise in your automobile is to install an aftermarket suspension system that uses plastic mounts. This is a synthetic material that is much stiffer than rubber, which means that it does a better job of isolating external sounds from the rest of the car.

A polyurethane bushing is often precision-engineered to provide a precise fit, which further minimizes noise and vibration. While aftermarket steering components can be significantly more expensive than stock systems, they offer a significant improvement in ride quality and make driving much quieter. You might be looking for a comfortable drive, a spring upgrade is an excellent way to achieve it.

5. Use Sound-Dampening Tape

One of the best ways to mute the noise from your vehicle is to wrap sound-dampening tape around your polyurethane bushings. The insulation will absorb vibrations and prevent them from being amplified by the metal components of your car. You can find acoustic insulation at most auto parts stores.

Simply cut the piece to size and adhesive it inside your bushes. The results may not be perfect, but they will be noticeable. Sound-dampening tape is relatively inexpensive, so it is worth a try if you are seeking a way to cut down on engine vibration.

Why Do Polyurethane Bushings Make Noise?

If you have ever wondered why your car’s suspension system generates sounds, you are not alone. Many auto owners have experienced the same thing and have attributed the vibration to their automobile’s shocks or struts. The true cause of the noise is often much simpler:

1. Worn out Bushings

As anyone who has ever driven a vehicle with worn-out bushings can attest, the resulting noise can be quite loud and annoying. Not only that, but it can also be dangerous, as it can make it difficult to hear other autos on the road.

There are several reasons why they may become obsolete, but one of the most common is simply aging. Over time, the rubber or plastic material that holds up the bushing will begin to break down, causing it to become thin and less effective at absorbing shocks.

2. Damaged Bushings

A damaged component can make polyurethane bushings loud. Too much weight or incorrect installation can wear them out over time. Broken bumpers will cause the metal to rub against the metal of the frame, which will create noise.

Eventually, the bushing will crumble if the metal wears away. In some cases, it is so severe that it cannot be repaired and the seal will have to be changed. For this reason, it is important to inspect your seals regularly and replace them if they need to be changed.

3. Loose Suspension Components

The bushings of suspension components can settle and loosen over a period of time, causing a gap within the part. This gap allows noise to escape, making a rattling sound whenever it moves. Broken springs can allow the support to move around more than it should, further exacerbating the problem.

4. Improper Installation

The fourth reason that polyurethane bushings may make noise is improper installation. If it is not installed correctly, it can cause components to become misaligned and allow metal-on-metal contact.

This can create a grinding or squeaking tone as the metal rubs against the metal. Also, you will need to ensure that when things are not tightened properly, they can spin on the shaft and possibly create vibrations.

5. Weighty Suspension

Many car makers use noise-canceling technology to keep their vehicles quiet. Some companies, like Jeep, have found that this technology can actually increase their vehicles noisier.

The reason for this is that weighty suspension systems can create a “booming” sound when they compress and decompress. This buzzing is amplified by the noise-canceling device and can be very annoying to drivers and passengers.

These are some of the main reasons for noisy polyurethane bushings. If you are having this problem, you should determine the cause in order to fix it. Otherwise, the sound will continue and may even get worse over time.

What is Polyurethane Bushings, and What Does It Do?

The polyurethane bushings are made of a synthetic polymer that is both strong and flexible. This material allows manufacturers to create bearings in a wide range of shapes and sizes. It also gives them the ability to tune the hardness of the plastic, which determines how much it will compress under load.

In suspension systems, polyurethane bushings are commonly used in many different ways. In a car, the spring connection connects the wheels to the frame and absorbs the impact of road bumps. The seals play an important role in this process by cushioning the connection between the two parts and absorbing vibrations.

FAQ’s

Let’s look at some of the most frequently asked questions to help you diagnose and treat this problem. It may be easier to solve than you think.

Is It Necessary to Replace the Bushings?

Many car owners are unsure of when they need to replace their bushings. In most cases, it is not required to fix them unless they are broken or severely worn out. If they are simply old, you can try lubricating them or installing a sound-deadening element. If they are cracked, you may need to repair them.

Replacing the rubber is a fairly simple process, but it is important to be sure you get the right ones for your car. Otherwise, you could end up causing more damage than good. With a little research and careful shopping, you can ensure that your car stays in excellent condition for years to come.

How Do I Know If My Bushings Are Damaged?

If you suspect that your bushings may be damaged, there are a few signs to look out for. Among the most obvious symptoms is increased noise when driving.

This can be caused by parts of your vehicle vibrating against each other and is typically most noticeable when driving on rough roads. Another indication that your rubber may need to be replaced is a decrease in riding comfort.

If you notice that your car feels less stable or smooth than it used to, this could be an indication that they are not absorbing vibrations as effectively as it once did.

If you are unsure whether or not your seals are broken, it is always best to consult a professional mechanic. They will be able to inspect your auto and give you an accurate diagnosis.

How Long Do Bushings Last?

Most rubber bushings are made from synthetic materials that are designed to last a long time. The conditions they are exposed to can cause them to degrade over long periods.

Those that are constantly exposed to sunlight or extreme temperatures will generally not perform as well as those that are protected from these elements. Parts that see a lot of use, such as those on a car’s suspension, will also tend to wear out more quickly.

Because of this, it is difficult to say exactly how many times they will hold up. In general, it is reasonable to expect that they will last for at least 15 years.

Do Polyurethane Bushings Improve Handling?

Any driver of a car can attest, that the quality of the ride is important. A smooth ride means less fatigue for the owner and passengers, and it also helps to preserve the vehicle itself. The most vital components of a comfortable ride are the braking mechanism, which helps to absorb shocks from bumps in the road.

The spring system consists of a number of different parts, including bushings. They are made from a variety of materials, but polyurethane is increasingly popular due to its durability and resistance to pests and chemicals.

While they may improve handling, they can also increase vibrations. As a result, it is necessary to weigh the pros and cons of this choice before choosing it for your vehicle.

Conclusion

With this information on how to quiet polyurethane bushings, you will be able to enjoy a smoother ride in your vehicle with them. To make sure that your rubber will last as much as possible, be sure to follow the tips above. You may also want to consider upgrading your suspension system for a longer-term, permanent solution.

We hope you have enjoyed this article. You must always be careful when working on your car’s parts as you can never be too cautious. Thank you for taking the time to read this article.