Last Updated on May 7, 2023

Installing an aftermarket lift kit on a vehicle is an increasingly popular choice for off-road enthusiasts. It increases the clearance of your vehicle, allowing you to easily drive over obstacles. But do lift kits really affect the braking and handling of your car?

Indeed! Installing after-market lift kits affect vehicle braking and handling. This is caused by increased stopping distance and changes in weight distribution which can alter your braking system.

If you’re considering installing a lift kit on your car and want to learn more about its potential impacts on your brakes, this article is for you. Keep reading to find out how lift kits can affect braking performance and vehicle handling.

Why Do Lift Kits Affect Braking and Handling: Reasons

Lift kits are used to improve the look and performance of a vehicle by increasing its ground clearance, but they can also lead to changes in braking and handling. Here are some of the ways that suspension lift kits can affect braking and vehicle handling:

Increased Stopping Distance

When a lift kit is installed on a vehicle, it shifts the center of gravity forward. This shift causes the vehicle’s weight to be pushed forward during braking, which results in an increase in stopping distance.

Also, this shift increases the pitch angle of the vehicle’s suspension system, which further reduces traction and contributes to longer stopping distances.

Changes in Weight Distribution

As mentioned earlier, installing a lift kit shifts the center of gravity and distributes weight differently than it would have otherwise been distributed without modification. This results in decreased traction and longer stopping distances compared to non-modified vehicles.

Also, these changes can make it difficult for drivers to modulate their braking force for precise control over their vehicle’s speed when needed.

Changes in Brake Pedal Feel

In addition to changing the weight distribution of a vehicle, installing a lift kit can also change the brake pedal feel by making it softer or spongier than before modification.

This makes it more difficult for drivers to accurately judge how much pressure they are applying to their brakes and subsequently can reduce their confidence while driving and increase their reaction times when approaching obstacles or hazards on the road ahead of them.

Lifted Suspension System

Lifting a vehicle’s suspension system alters its geometry, changing the angles at which the brakes operate. This can cause increased pedal travel time (how long it takes to apply pressure to the brakes) and decreased braking power.

The greater angles created by a suspension lift kit may also cause increased wear on brake pads over time due to higher friction levels when applied. Additionally, unbalanced or mismatched tires with a lifted suspension system could disrupt overall traction control and lead to poor stopping distances.

Require Larger Wheels and Tires

Using larger tires is another way lift kits can negatively affect braking efficiency and handling. When increasing wheel size along with lifting a vehicle’s suspension system, rotational mass increases, leading to more energy required from brakes to stop the vehicle safely.

Not only does this reduce the effectiveness of brakes, it can also decrease fuel efficiency and cause excessive tire wear over time due to the strain on rubber compounds during hard braking applications.

Reduced Brake Line Pressure

Lift kits can cause brake lines to stretch or become misaligned, reducing the hydraulic pressure needed for efficient braking force production.

When brake lines become stretched or misaligned due to lifting a vehicle’s suspension system, it results in decreased pedal firmness (brakes feel spongy upon application) and longer pedal travel times than normal (as mentioned earlier).

This reduced pressure in brake systems can be dangerous as drivers inherently require more effort when exerting pressure on brake pedals to stop vehicles quickly and safely.

How Do You Tell If Your Lifted Vehicle’s Brakes Need Fixing?

Maintaining the safety of your lifted truck or vehicle is key, and the brakes are an essential element of that. Understanding how to tell if they need fixing can help you stay safe on the roads. Here are some signs to look out for:

Longer Stopping Distances

If it takes longer for your lifted vehicle to stop than usual, you should get your brakes checked by a professional mechanic. This could indicate a malfunction in the braking system. If this issue persists, you may also want to check if other brake components, like calipers or pads, require replacing or adjusting.

Also, examine the condition of hoses, lines, and other parts related to the brake system for potential leaks or damage that could reduce their efficiency.

Soft or Spongy Brake Pedal

If your brake pedal feels spongy when you apply pressure on it, or it sinks closer to the floor than normal when pushed down, this could mean the air is in your braking system.

Air bubbles cause a decrease in hydraulic pressure, slowing down your stopping power and making it dangerous for driving. It would be best to have a professional technician inspect and fix any air leaks so your brakes will work properly again.

Vehicle Pulls To One Side When Braking

If you notice that when braking, your vehicle starts to pull towards one side instead of staying straight, there may be an issue with its suspension system or brakes. Uneven brake pad wear can cause an imbalance in friction between each wheel, resulting in this pulling sensation during braking.

Grinding or Squeaking Noise When Braking

While slowing down, your brakes may make grinding or squeaking sounds, which might mean something’s wrong with your brake pads or discs or possibly other parts like springs and clips that hold them in place.

It might also indicate low levels of grease, which reduce friction between these components and cause them to grind together during operation. Again, it is essential to get this checked by a professional to avoid further damage due to the continued use of faulty brakes.

Vibration When Braking

Vibration during braking could signal an issue such as warped rotors due to excessive heat buildup caused by aggressive usages, such as hard stopping at high speeds or frequently hauling heavy loads up steep inclines without giving enough time for cooling off periods between uses.

Warped rotors are dangerous since they cause less effective contact between the brake pad and rotor, resulting in slower response times during emergency stops. This can lead to costly accidents if not addressed promptly by replacing them before further use begins.

How to Improve Vehicle Braking System After Installing Lift Kit?

When it comes to upgrading a vehicle’s braking system after mounting a lift kit, there are several steps you can take to ensure optimal performance:

Upgrade the Braking System

Upgrading the braking system on your vehicle after installing a suspension lift kit is one of the most effective ways to maximize overall safety and performance.

Depending on your make and model, this could involve upgrading to more powerful brakes altogether or simply replacing worn-out parts affected by the increase in ride height.

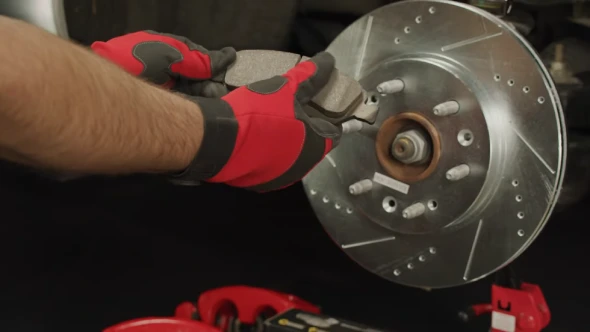

If you want improved power, consider replacing disc brakes with larger rotors and calipers with better performance and reliability. Swapping out old brake lines for stainless steel braided lines will reduce flexing due to increased suspension travel and ensure a smooth pedal feel under hard braking situations.

Adjust the Brake Proportioning Valve

When lifting a vehicle, it is essential to adjust the brake proportioning valve as part of the process. This valve helps regulate how much hydraulic pressure goes to each wheel when applying brakes, allowing you to fine-tune performance when lifting or lowering your ride height.

To adjust this valve correctly, use a pressure gauge or bleeder tube on each wheel cylinder while applying pressure. This will help determine how far open or closed each wheel’s valve should be set for a proper balance between front and rear wheel stopping power.

Use High-Quality Brake Components

Using premium brake components when upgrading your vehicle’s brakes after installing a suspension lift kit can ensure optimal performance from your new setup.

In addition to larger rotors and calipers for increased stopping power, consider investing in higher-performance pads and shoes that both wear slower and provide more responsive modulation.

By adequately installing these components and upgrading lines for better fluid flow throughout the braking system, you can ensure optimal brake performance no matter the terrain you drive on.

Adjust Driving Habits

In addition to modifying and upgrading components of your vehicle’s braking system after installing a car or truck lift kit, it’s also essential to adjust driving habits accordingly to maximize performance while reducing wear and tear on those same components over time.

For example, drivers should try not to use their brakes too often when descending steep hills since this puts additional strain on all components of their vehicles’ braking systems resulting in accelerated wear and tear over time.

Additionally, drivers should try not to ride their brakes excessively. Keeping their foot hovering over them during normal driving conditions contributes to additional wear even when no action is taken.

Regularly Maintain the Braking System

Finally, after installing a lift kit into your vehicle, regular maintenance of all aspects of its braking system becomes increasingly important to keep everything running optimally.

This includes:

- Regularly checking & replacing brake pads & rotors,

- Flushing out the old brake fluid,

- Inspecting all lines for leaks or damage,

- Checks & balances depend upon individual usage.

By regularly performing all necessary maintenance items, drivers can rest assured knowing that their vehicles can operate safely even under more challenging conditions.

What to Replace After Installing a Lift Kit to Improve Braking System?

After installing the lift kit, you might have to replace some brake system components to maximize your vehicle’s performance. This includes replacing the trailing and control arms, essential components for proper suspension geometry and braking performance.

Trailing arms connect the vehicle’s frame and the axle assembly, allowing them to move together on an arc-like trajectory when cornering. Due to improper alignment, rust, or corrosion, trailing arms can wear out over time.

Replacing these parts will ensure your suspension geometry remains correct and your brakes will be more responsive.

Control arms connect two rigid suspension system parts on either side of the wheel hub assembly. They allow these parts to move relative to each other while maintaining proper suspension geometry.

Like trailing arms, control arms can become worn over time due to poor alignment or corrosion, resulting in decreased braking performance. Replacing these with high-quality aftermarket options can help restore proper suspension geometry and improve overall braking performance.

Aftermarket Lift Kits: Weigh the Braking Improvements

Installing an upgrade lift kit on your car can be an excellent upgrade for many reasons, but it is essential to fully consider the drawbacks before attempting such a modification. Lift kits change the car’s weight distribution, decreasing braking performance and reducing overall vehicle control.

If these issues are not adequately addressed, you’ll have more driving problems in the future. To prevent this from happening, being aware of the potential risks associated with aftermarket lift kits is critical before purchasing. That information lets you decide whether a lift kit fits your driving goals.