Last Updated on April 19, 2023

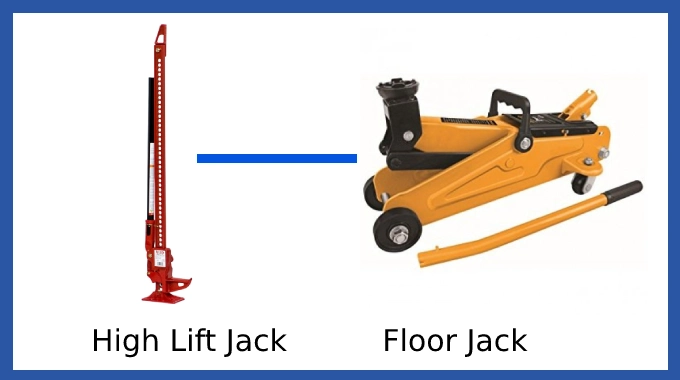

High-lift jacks have become increasingly popular as recovery tools for drivers of all kinds. This is not surprising, considering high lift jacks offer multiple uses. Unlike a standard floor jack, which can typically only lift a car off the ground enough for tire repair, a high lift jack can act as both a winch and vehicle hoist.

Even though both have their benefits, understanding why one is better than the other can help you decide which one is right for you. Weight capacity, height reach, and safety features should all be taken into account. There’s no shortage of things worth considering when comparing these two jacks.

Don’t get stuck in an uncertain situation. Let’s explore the differences and why a high-lift jack makes more sense.

The Differences Between A Floor Jack Vs High Lift

Regarding automotive jacks, two of the most popular choices are floor jacks and high lift jacks. Although both can provide a great deal of convenience when lifting heavier items, they work in very different ways and have unique advantages.

Here are the main differences between a floor jack and a high lift:

01: Design

Floor jacks are designed specifically to fit under vehicles that sit closer to the ground, allowing them to be used in tight spaces. This is achieved through a low-profile design with a two-piece handle and socket construction for extended longevity.

Alternatively, high lifts are created for more versatility and can be used for a variety of purposes beyond just vehicle repair. The design of a high lift also differs from a floor jack as they feature an adjustable handle with one solid piece construction that locks at multiple points along its length.

02: Purpose

The purpose of a floor jack and high lift can vary significantly based on what you plan to use them for. Floor jacks are most commonly utilized for lifting vehicles up during maintenance and repairs, as well as when changing tires or performing oil changes.

High lifts can be used for much more than just car repair. They can be utilized in multiple settings, including lifting heavy objects such as pallets, logs, stumps, or any other object that requires extreme power to move it.

Many people also use high lifts as winches to drag heavy objects out of difficult terrains such as mud or snowbanks.

03: Lifting Capacity

The lifting capacity of both a floor jack and a high lift will depend on their individual models. Typically floor jacks have lower weight limits than those of high lifts. Most standard floor jacks can carry up to around 5,500 lbs, while some higher-end models may carry slightly more weight.

Conversely, most standard high lifts can easily lift up to 7,000 lbs or more, depending on their individual model type. It makes them better suited for heavier loads over longer distances than their lower-profile counterparts.

04: Portability & Storage Space

Regarding portability and storage space, the main difference between a floor jack and a high lift is their size and weight.

Floor jacks are typically much larger and heavier than high lifts, weighing in at 30 to 70 pounds compared to 10 to 30 pounds for a high lift. Consequently, they do not have the same portability and are more difficult to move.

On the other hand, high lifts are much easier to transport and take up much less storage space, making them ideal for those with limited storage rooms or who need to travel with their tools.

05: Height Range

The height range of a floor jack versus a high lift is another major difference between the two tools. Floor jacks are typically designed for lifting objects 14 inches off the ground, whereas high lifts can often lift objects up to 60 inches in the air.

This makes them ideal for reaching higher areas without a floor jack, such as changing tires on large vehicles or working under cars with low clearance.

06: Stability

Regarding stability, floor jacks tend to be more reliable than high lifts due to their wider base and lower center of gravity.

The wider base of floor jacks helps distribute weight evenly, which reduces the risk of tipping over during use. A lower center of gravity makes them less likely to tip over while lifting heavy objects.

Because high lifts have higher centers of gravity, they are more likely to become unbalanced when used incorrectly or with heavy items.

Also, floor jacks have stronger frames that make them even more stable when used correctly, unlike high lifts, which can bend if not handled carefully enough.

07: Durability

Floor jacks and high lifts are long-lasting if you take care of them. But high lifts are even more durable because they can handle heavier loads and tougher conditions. Many high-lift models also have overload protection systems to keep them from getting damaged when lifting too much weight.

08: Versatility

In terms of versatility, both types of lifting tools offer plenty of options but with different results depending on your specific needs.

Floor jacks are ideal for quick one-off lifting tasks such as changing tires at home while still providing enough power for light-duty work around the shop or garage area.

High lifts offer much greater versatility due to their increased weight capacity and height range. They can lift heavy stuff at construction sites without the risk of damage from excess pressure or load weights outside their intended range.

09: Safety features

Hydraulic floor lifting jacks have different safety features depending on the model. Floor jacks usually come with overload protection and a valve that locks when it lifts something off the ground.

High Lifts are safer to use for heavier loads because they have more safety features, like anti-skid surfaces and locking mechanisms.

10: Ease of Use

Floor jacks are incredibly user-friendly, as they mostly feature a hydraulic lifting mechanism. This allows the user to easily and quickly get beneath the car’s body. On the other hand, high lifts require more manual effort as a pump or a lever typically operates them.

The size and weight of floor jacks are usually smaller and lighter than those of high lifts, which makes them easier to move and store. A floor jack also has the advantage of fitting under cars with low clearance without needing additional adapters or extensions.

11: Cost

Regarding cost comparison between floor jacks and high lifts, floor jacks are more expensive than their high lift counterparts.

This is mainly due to their portability and low-profile design, which makes them perfect for vehicles with low clearance. Furthermore, floor jacks often come with safety features such as overload protection which increase their overall cost.

High lifts tend to be cheaper due to their simpler design which does not require extra features such as overload protection. And they may not be suitable for low-clearance vehicles due to their design and height when fully extended.

Exactly Why Do We Need a High Lift & Floor Jack?

High-lifts are designed for changing tires and lifting stuck wheels or lifting truck bellies off the ground. A reminder that high-lifts should never be used for an extended period of time, as this increases the risk of overheating and failure.

To safely use a high lift, you must first ensure that the jack stand is correctly placed under your vehicle and that the base of the jack is firmly on the ground. Once in place, you can then pump the handle until you reach your desired height.

Note: When lifting with a high lift, keep an eye on any nearby bystanders and anything else that a falling object could hit.

Floor jacks are different from high lifts in that they operate solely by hydraulics and provide a more stable platform while lifting heavier objects such as cars or small tractors. Floor jacks feature casters that allow them to be easily moved around.

Which is great when trying to get into tight spaces or performing maintenance beneath your vehicle without needing help from another person. When using a floor jack, it is important not to exceed its rated capacity or lift too high off the ground. If something goes wrong, either can put unnecessary stress on its components.

How Much Weight Can a High-Lift Jack Hold?

A high-lift Jack is designed to provide extra lifting capacity compared to that offered by traditional floor jacks. Its rated capacity is around 4,660 lbs (2114 kg), and it has been tested to lift up to 7,000 lbs (3175 kg).

This makes it an ideal choice for heavier load capacity or jobs requiring a greater degree of precision since it allows you to achieve higher accuracy in the lift. The high-lift Jack is also lightweight and easy to maneuver, meaning that you can use it in tight spaces or areas where other larger jacks might not fit.

Note: Its design allows for various uses, including winching, clamping, and pushing as well as lifting.

How Much Weight Can a Floor Jack Hold?

A floor jack typically has a maximum weight capacity of 3 – 4 tons (6,000 – 8,000 pounds). This means they can lift cars and light trucks with ease. Floor jacks are great for general maintenance, such as changing tires or performing oil changes.

They are also great for raising heavy loads so that you can install new parts or perform repairs underneath them. Despite this, a floor jack or trolley jack has limitations as they cannot be used for more specialized tasks such as winching or clamping as the High-Lift Jack can.

Why Do High-Lift Jacks Fail?

High-Lift Jacks fail for a variety of reasons. The most common cause is improper use. If the jack is not properly rated to handle the weight of the load, then it can fail and cause injury or property damage. Additionally, if the jack is not placed on a level surface and stabilized correctly, it can shift or even tip over while in use.

When lifting heavy objects, the release valve may not remain open, causing air to be trapped in the cylinder and causing difficulties with lifting or lowering the object. High-lift jacks are also prone to rusting, weakening structural components and leading to unexpected failures.

Also, extreme force is typically required to lift the load when using a high lift jack. If this force is not applied with precision, it can cause the jack to kick back due to the sudden release of energy.

What Makes Floor Jacks Fail?

Floor jacks can experience failure due to several factors. First and foremost, improper maintenance is one of the most common causes of failure. Unless seals, hoses, and other components are maintained and serviced regularly, they can wear out or crack, resulting in leaks and pressure loss.

Meanwhile, any sudden jerking motion or vibration while in use can lead to an unexpected failure as well as exceeding its weight capacity. It is also possible for check balls to degrade over time and no longer be able to move hydraulic fluid between chambers properly. This reduces their effectiveness as effective lifting devices.

How to Use a Floor Jack on a Car?

Using a floor jack on a car can be a bit tricky, but with proper instructions, you can do it safely and with ease. Here are the general steps to follow:

- Make sure the car is on a level surface, and the parking brake is engaged.

- Find the correct lifting point on the car, which can be found in the owner’s manual or on the car’s frame.

- Position the floor jack so that it is centered under the lifting point.

- Pump the handle of the floor jack to lift the car off the ground.

- Once the car is off the ground, place a jack stand under the car’s frame or designated jack points to hold the car in place while you work.

- Slowly lower the car onto the jack stands, making sure that the stands are securely in place before releasing the weight of the car from the floor jack.

- When you are finished working, use a floor jack to lift the car slightly so that you can remove the jack stands and then lower the car back to the ground.

It’s important to always use jack stands in conjunction with a floor jack to ensure the safety of yourself and anyone else working on or around the car. Never work under a car that is only supported by a floor jack, as this can be extremely dangerous.

How Do You Jack Up a Car with a High Lift?

- Always keep your face and body clear of the jack to prevent injury.

- Apply lubricant, such as lanolin, to the mechanism for smooth operation.

- Clean the base of the jack before use and position it close to the wheel for stability.

- Use a baseplate or wheel lift accessory when jacking the car lift.

- Grasp the jack handle upright and apply grease or oil for smoother operation while lifting the vehicle by operating the lever in the raised position.

- Lower the vehicle by flicking the direction lever until the desired height is reached, then lower the jack completely after removing accessories used during the process.

- Place rocks, logs, sand, or mud under raised wheels once the job is complete to ensure stability.

Can You Use a High Lift Jack to Change a Tire?

High lift jacks are designed for specific purposes, such as lifting vehicles out of ruts or over obstacles. They aren’t designed with safety features in place, so their use when changing tires could potentially lead to damage occurring or someone getting hurt if proper caution isn’t taken during operation.

For tire changes and other related activities, it’s best to use proper jacks such as scissors or hydraulic types, which offer much greater stability and security when lifting than those offered by high-lift jacks do.

Be sure to follow all manufacturer guidelines for usage and pay close attention to any damages or defects in order for your efforts to remain safe and effective throughout the process.

What’s Better When Changing a Tire: a Hi-Lift Or Floor Jack?

When it comes to changing a tire, the floor jack is by far your best bet. Floor jacks are specifically designed for lifting vehicles and offer greater stability than hi-lift jacks. They are also much easier to use since they usually come with their own hydraulic pump that helps you raise and lower the vehicle.

When using a floor jack, you can raise the vehicle up to a comfortable height so you can easily access the tire. Plus, with its four support points, it’s also less likely to tip over when compared to a hi lift jack, which has only two support points.

On top of that, many floor jacks come with special features such as adjustable extensions. These allow you to reach higher or lower areas on the car for added convenience.

Although, a high lift jack can also be used to change a tire. But due to its higher risk of tipping over, it’s not recommended for the general public. It’s best left to professionals who are experienced in using hi-lift jacks and know how to safely use them.

Is It Possible to Add More Height to a Floor Jack?

If you’re looking to increase your floor jack’s height and lifting capacity, there are options available for you. Using supplemental lifting blocks or targeted attachments can extend the ability of your existing model.

These attachments will typically add an extra few inches of height onto the existing structure of the jack, allowing you to lift heavier objects more safely and efficiently. In the meantime, remember that adding more height may also reduce the stability of your jack and should only be done if absolutely necessary.

Is a High-Lift Jack Capable of Applying More Force Than a Floor Jack?

A high-lift jack has the incredible ability to apply far greater force than a regular floor jack. Which is why they are often used in various scenarios, such as off-roading or other situations where getting a vehicle unstuck is necessary. The design and construction of the two jacks account for this difference.

While a floor jack simply lifts with hydraulic pressure, a high lift offers greater leverage thanks to its extended arm and pulley system. This allows the high-lift jack to operate with greater pulling power, allowing it to work even in extreme conditions that would be too difficult for a floor car jack.

High lift jacks have revolutionized how people can recover their vehicles from tough spots. The longer arm provides a mechanical advantage that multiplies the applied effort over a larger area, resulting in greater lifting power.

Can a 2 Ton Floor Jack Lift a Car?

Typically, a 2-ton floor jack can handle up to 4,000 pounds of weight. This is more than enough for most sedans and other smaller cars.

To use one safely and effectively, it’s important that you select the right size jack for your type of car and read any instructions that come with the product before proceeding. And always make sure that the car is on level ground and that the jack is positioned securely before attempting to use it.

Also, using chocks or wheel blocks on the opposite side of the car from where you are jacking is recommended as an extra safety precaution. Lastly, when finished, properly lower the vehicle back down and remove any blocks or chocks before driving away.

Deciding Your Car’s Essential Lift: High vs. Floor Jack

It can be difficult to decide between a floor jack and a high lift. However, if you need extra power to handle bigger jobs, such as lifting heavy items or applying more torque, then a high lift may just be your best bet. A reliable choice for laboratory work requiring additional height.

Even so, a traditional floor jack will do fine if your needs are more basic and weight isn’t an issue. Whichever type of tool you choose, ensure that it meets all the relevant safety standards and is suitable for your specific needs. In this way, you can be assured that whatever you set out to do will be done safely and reliably.